1-800-833-7958 | Sales@geotechenv.com | Find a Location | Español | 中文 |

Geotech Single & Multi-Well AC Sipper

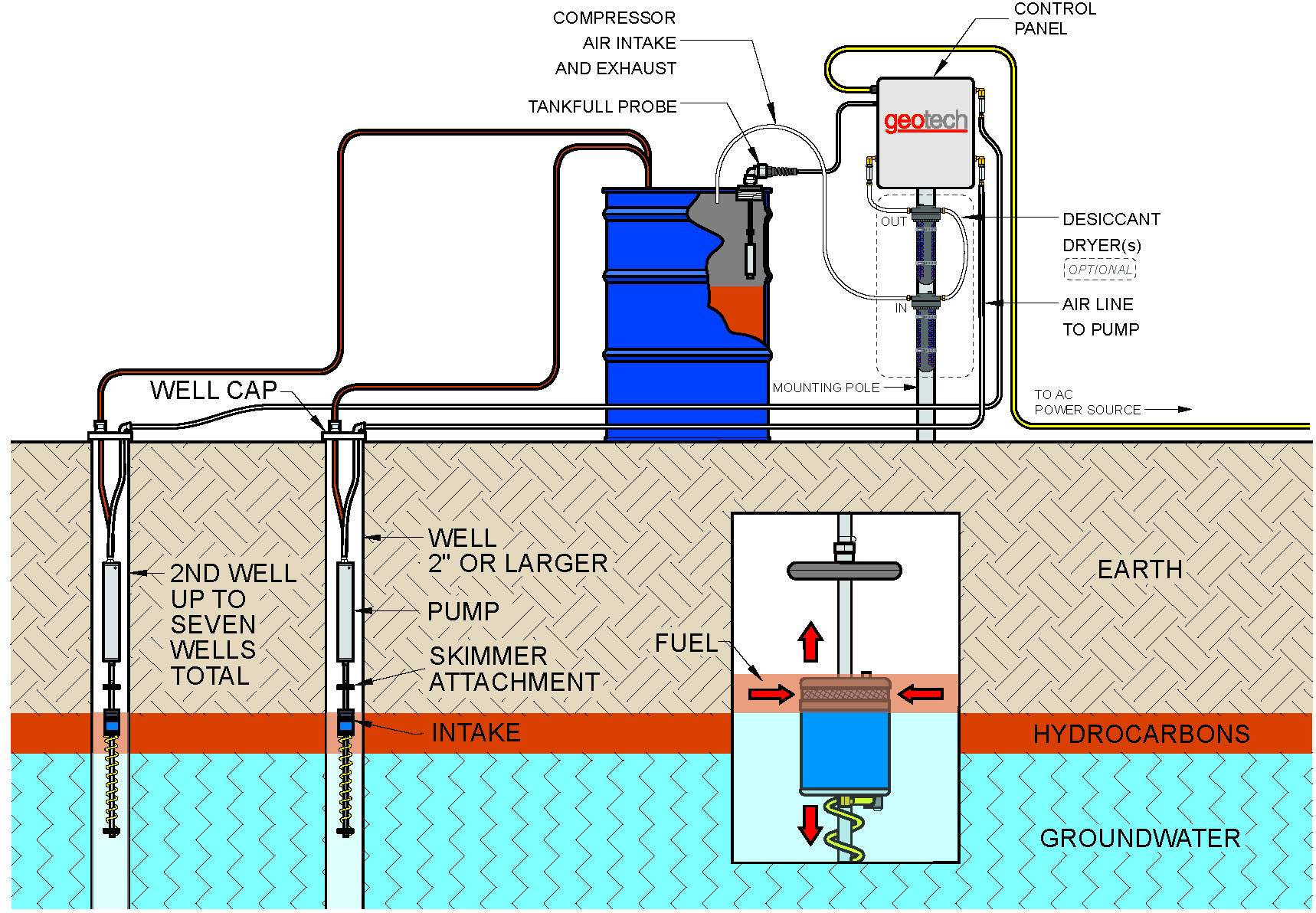

The Geotech AC Sipper is a Single-Phase, 110-220V AC, powered remediation system, designed for recovery applications where electrical power is available. This uniquely flexible system can be configured for up to seven wells. The compact, easy-to-install features make this unit an industry favorite!

The AC Sipper uses a unique downwell pump to recover hydrocarbons through a floating oleophilic/hydrophobic intake filter. Once the pump canister is filled via the vacuum cycle, the pump reverses, pressurizes the system and pumps the recovered fluid to the surface and into a storage vessel.

The Geotech AC Sipper can effectively extract fluids from depths to 180 feet below ground surface and recover viscous hydrocarbons such as 90 weight oil when our heavy oil skimmer is utilized.

- Available in single or multi-well configurations

- Solar powered versions are also available

The Geotech AC Sipper recovers floating hydrocarbons (LNAPL) from wells using an AC powered pressure/vacuum pump. The standard Skimmer features a unique product intake assembly that incorporates both a density float and an oleophilic/hydrophobic filter that differentiates between floating hydrocarbons and water. The skimmer floats just above the oil/water interface to collect and remove hydrocarbons from the well into an optional above ground storage tank.

The Geotech AC Sipper is also available for recovery of sinking product (DNAPL) from wells when using a fixed intake.

| Applications: | 2" (50 mm) or larger recovery wells | ||

| Recovery Rate: | .2 gallons (757 ml) per cycle | ||

| Maximum Operating Depth: |

180 feet (55m) | ||

| Power Requirements: |

87 to 240 Volts AC 2.7 to 1 Amp(s) |

||

| Maximum Pressure: | 100 PSIG (7 bar) | ||

| Maximum Vacuum: | 20" Hg @ MSL (50mm Hg) | ||

| Oil ⁄ Water Separation: | Oleophilic/hydrophobic mesh screen | ||

| Controller: | |||

| Operating Temperature | 32° to 104°F (0° to 40°C) | ||

| Storage Temperature Range | -20° to 150°F (-29° to 66°C) |

||

| Humidity | 90% non-condensing (max.) | ||

| Size | 10" D x 18" T x 16" W (25.4 cm D x 45.7 cm T x 40.6 cm W) | ||

| Approximate Weight |

35 lbs. (15.9 kg) single channel 51 lbs. (23.1 kg) eight channel |

||

| Rating | NEMA 3R | ||

| Optional Downwell Pump: | |||

| Size | 23.5" L x 1.75" OD (59.7 cm L x 4.4 cm OD) | ||

| Weight | 4.5 lbs. (2.04 kg) | ||

| Materials |

303 and 304 Stainless Steel, Flexible Rubber Tubing, PVC, Brass | ||

| Optional Skimmer Assemblies: | 2" Model | 4" Model | |

| Effective Travel Range | 12" (30.5cm) | 24" (61 cm) | |

| Size |

35.5" L x 1.75" OD (90.2 cm L x 4.4 cm OD) |

35.5" L x 3.75" OD (90.2 cm L x 9.5 cm OD) |

|

| Weight | 1.75 lbs. (.79 kg) | 2.25 lbs. (1.02 kg) | |

| Operating Temperature | 32° to 104°F (0° to 40°C) | ||

| Storage Temperature | -20° to 150°F (-29° to 66°C) | ||

| Materials | 304 Stainless Steel, Polyethylene, PVC, Polypropylene, Brass | ||

| Optional Tubing: | |||

| Air | .17" ID (4.3mm ID) | ||

| Discharge

|

.375" ID (9.5mm ID) | ||

Step 1: Control Panel

Choose from 1 to 7 wells

- NEMA 3R Enclosure

- Tankfull Shut-Off Switch (¾" or 2" NPT bung-fitting)

- Microprocessor Controlled 2-Line LCD Display with four scroll buttons

- On/Off Switch

- Pressure/Vacuum Pump

- Pressure/Vacuum Gauge

Solar powered versions are available

Step 2: Downwell Equipment

Downwell Pump(s)

- Standard

- With Conductivity Sensor

Skimmer(s)

- 2" or 4" Skimmer with 100 or 60 Mesh Intake

- 2" or 4" Protective Screen

- 4" Skimmer with Extended Travel

- 4" Heavy Oil Skimmer

- 4" High Temperature/Heavy Oil Skimmer

- 2" DNAPL Intake

Other Options:

- 2" or 4" Slip Fit Well Cap(s)

- Choose Length: Air and Discharge Tubing

- 55 Gallon Steel Product Drum(s)

- Tank Manifold: 2 to 7 Wells

- Dual-Wall Containment Product Recovery Tank(s)

- Lockable Weatherproof Enclosure

- Trailer for Mounting Mobile System

- SitePro with SiteView Telemetry

Control Panel and Pressure/Vacuum Pump (seven-well controller shown)  Downwell Pump, with 2" and 4" Skimmers |