1-800-833-7958 | Sales@geotechenv.com | Find a Location | Español | 中文 |

Geotech LO-PRO™ Air Strippers

Low Profile Air Strippers

Geotech LO-PRO™ Air Stripper Models II and III are highly efficient water treatment systems that can remove up to 99.99% of many volatile organic compounds (VOCs) from water.

Systems are self-contained for use in limited space applications.

- Patented multi-stage counterflow aeration provides up to 99.99% removal efficiency.

- Features vacuum induced draft design that is more efficient than forced draft and eliminates fluid leakage between trays.

- Low profile modular design requires less floor and head space.

- Lightweight modular polyethylene trays allows the addition or subtraction of trays to meet engineered treatment requirements.

- Stainless steel bubble plate design resists fouling.

- Highly effective on BTEX, MTBE, and Radon.

- Very easy to install and maintain.

- Remote monitoring and troubleshooting capability with the optional Geotech ECM.

| LO-PRO Model II | LO-PRO Model III | |

| Applications: | For use in non-classified and Class 1, Div. 2 locations |

High flow-rate for use in non-classified and Class 1, Div. 2 locations |

| Dimensions: | 5 tray unit: 66"L x 27"W x 75"H Each additional tray adds 10" to height |

3 tray unit: 91"L x 60"W x 70"H Each additional tray adds 13" to height |

| Max. No. of Trays: | 8 | 5 |

| Material: | Linear Low Density Polyethylene Housing Stainless steel bubble plates* | Light Weight Polyethylene Housing Stainless steel bubble plates* |

| Water Flow: | 1-20 gpm (4-76 l /min)** | 1-60 gpm (4-227 l /min)** |

| Air Flow: | Up to 250 CFM (7.1 CMM) | Up to 1100 CFM (31 CMM) |

| Blower HP: | 1-5 HP regenerative blower (TEFC: for use in Class 1, Div. 2 locations) |

10-15 HP centrifugal blower (TEFC: for use in Class 1, Div. 2 locations) |

| Blower Voltage: | 208-230/460V, 50 Hz or 60 Hz, 3 phase Single phase available |

208-230/460V, 50 Hz or 60 Hz, 3 phase |

| Options: | High pressure switch assembly, low pressure switch assembly, Geotech ECM controls and telemetry, motor starter package, sump water level sensor, additional trays, CFM gauge and valve assembly, transfer pumps. Explosion-proof blower. |

High pressure switch assembly, low pressure switch assembly, Geotech ECM controls and telemetry, motor starter package, sump water level sensor, additional trays, CFM gauge and valve assembly, transfer pumps. Explosion-proof blower. |

| *All-stainless steel versions available. **Higher flow versions available. |

||

Contaminated water enters the Geotech LO-PRO at the top of the unit and cascades onto the first of a series of stainless steel bubble plates. A baffle in the center of each plate redirects the water 180° in each stage as it flows downward, alternating between clockwise and counterclockwise directions. This action optimizes the residence time of the water in the Geotech LO-PRO, allowing for efficient contaminant removal.

|

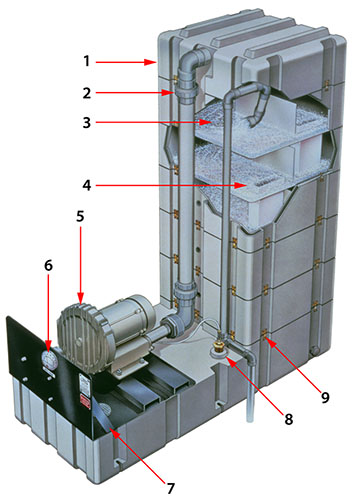

1 Lightweight polyethylene construction 2 Threaded coupling for easy assembly 3 Stainless steel bubble plates 4 Multi-stage counterflow aeration 5 Blower 6 Blower pressure gauge 7 Air inlet 8 Sump water level sensor 9 Hand operated latches |

|

| Geotech LO-PRO™ Model II |

| Geotech LO-PRO™ Model III S |